Nowadays, "chip" has become a high-frequency word.

Chip is the collective name of semiconductor component products, equivalent to the brain of electronic products, and wafers are also known as "chip carrier", therefore, wafer manufacturing is a key part of the entire chip industry chain.

And it is this electronic product full of high technology, every day from Rizhao High-tech Zone is sent to the country and even around the world.

Ltd. is a Hong Kong-funded enterprise, which is engaged in the development of integrated circuits and wafer manufacturing. Since it signed a contract in Rizhao High-tech Zone in 2019, it has aimed at the frontier of high technology, research and development and production of wafer manufacturing, and opened a strong "core" to the "core". The road of "core".

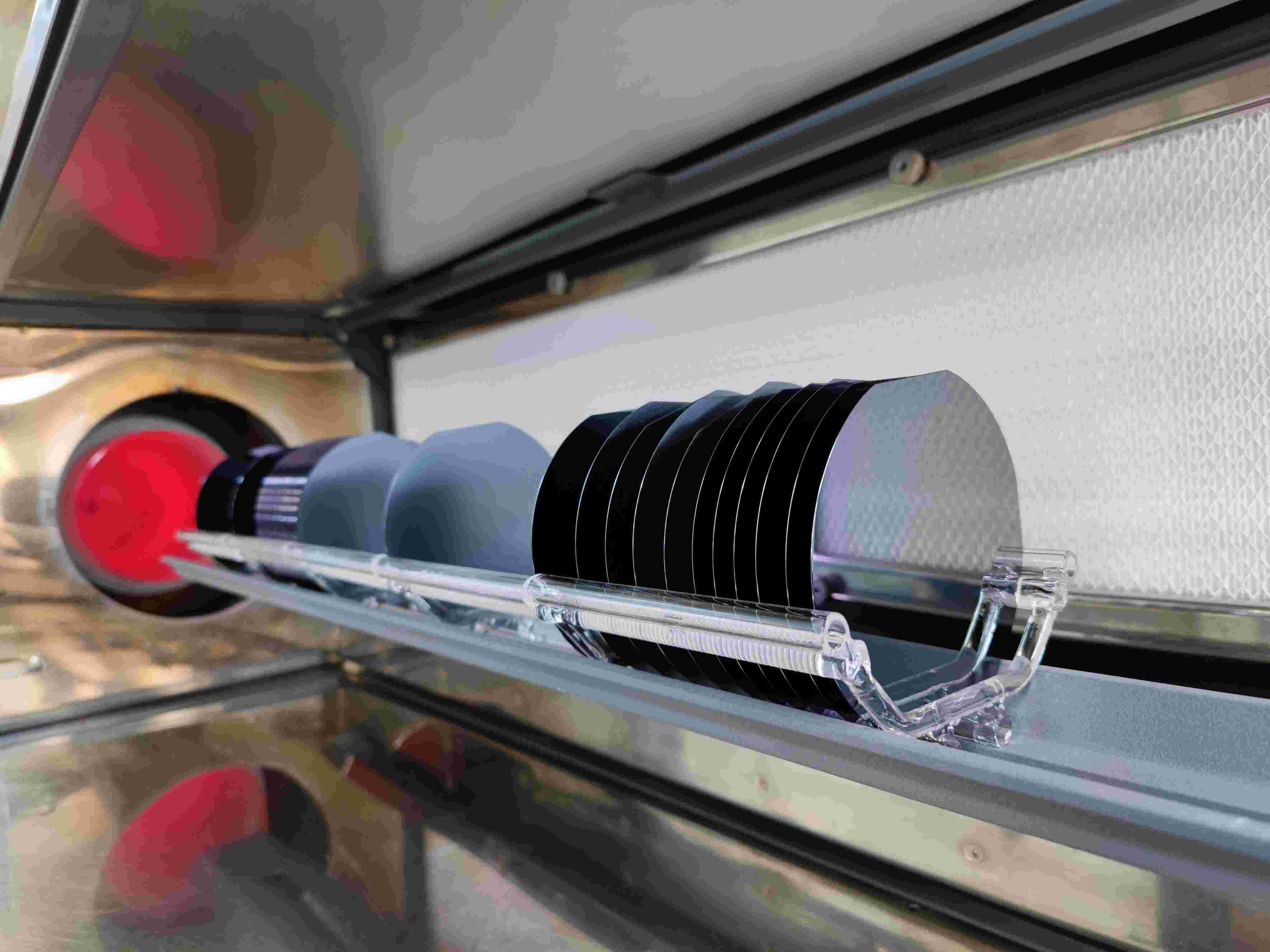

What is a wafer? Wafer is the manufacture of semiconductor transistors or integrated circuit substrate, is a crystal material, its shape is round, so called wafers.

Into the Xinghua Semiconductor, exhibition cabinets full of semiconductor products look ordinary, each piece but contains technology patents.

"This is our main production of wafer products." Ltd. Deputy General Manager Yu Kai Lin introduced to reporters, in a diameter of 5 inches on the wafer, distributed tens of thousands of integrated circuits or power device chips, only under a magnifying glass to see, and in the integrated circuit internal circuit wire width of only 0.5µm.

Ltd., the company was the first to understand and develop the semiconductor manufacturing industry in Southeast Asia, carrying out semiconductor product design, manufacturing and sales, and was the first integrated circuit manufacturer to develop and produce lithium battery protection circuits, calculator circuits, and clock circuits, which has strongly promoted the development of the domestic semiconductor industry. When the company was operating in the wafer manufacturing plant, the monthly output had exceeded 15,000 wafers for a long time, with a wafer-out rate of more than 95% and a single wafer yield rate of more than 97%, all of which were at the leading level in the industry, and passed the quality system certification of ISO9001-2008.

"The Xinghua Semiconductor project builds two 5-inch/6-inch wafer production lines at the 0.5µm process level, which will be upgraded through two years to reach an annual production capacity of 360,000 wafer designs." Yan Lieyi, general manager of Shandong Xinghua Semiconductor Co., Ltd. said, at present, the company mainly constructs one 6-inch semiconductor integrated circuit production line of 0.5µm, mainly designs and manufactures semiconductor discrete devices and integrated circuit chips with broad market prospect, and the products include high-speed switching tubes, light-sensitive integrated circuit wafers, etc. It is one of the main domestic suppliers of small signal transistors, power transistors and switching tube manufacturing.

Innovation is inseparable from talents. As a technology-intensive and knowledge-intensive industry, the development of the enterprise needs a constant source of talent support.

"We have a dedicated technical team, all long engaged in the development and production of integrated circuit wafers, as well as a number of senior engineers in product development, wafer manufacturing, equipment maintenance. Yan Lieyi introduced, talent advantage is the development of enterprises "hard core power".

At present, Shandong Xinghua Semiconductor has produced more than 30,000 wafers, products sold to the United States, India and other places. The second phase of the project is mainly to build 0.18µm process level of 8-inch wafer production line, with a monthly capacity of 50,000 wafers.

"To build a chip with our own intellectual property rights, we are duty-bound to do so." Looking to the future, Shandong Xinghua Semiconductor is full of confidence, and the road of strong "core" will become broader and broader.